As global food safety and traceability standards continue to increase, laser marking technology is rapidly becoming the preferred identification method for food packaging. Compared with traditional inkjet printers, laser coders offer permanent, high-precision, eco-friendly, and zero-consumable marking. This makes laser marking an ideal solution for production date coding, batch numbers, QR codes, and traceability codes in the food industry.

DAT Laser, a leading manufacturer of industrial laser marking systems, provides high-performance, cost-effective solutions customized for food production lines. Our laser makers help manufacturers improve efficiency, ensure compliance with global food standards, and reduce long-term operating costs.

The introduction of laser marking has greatly improved the level of identification technology. When applied to food packaging, laser marking offers several advantages:

Low maintenance rate

High marking speed

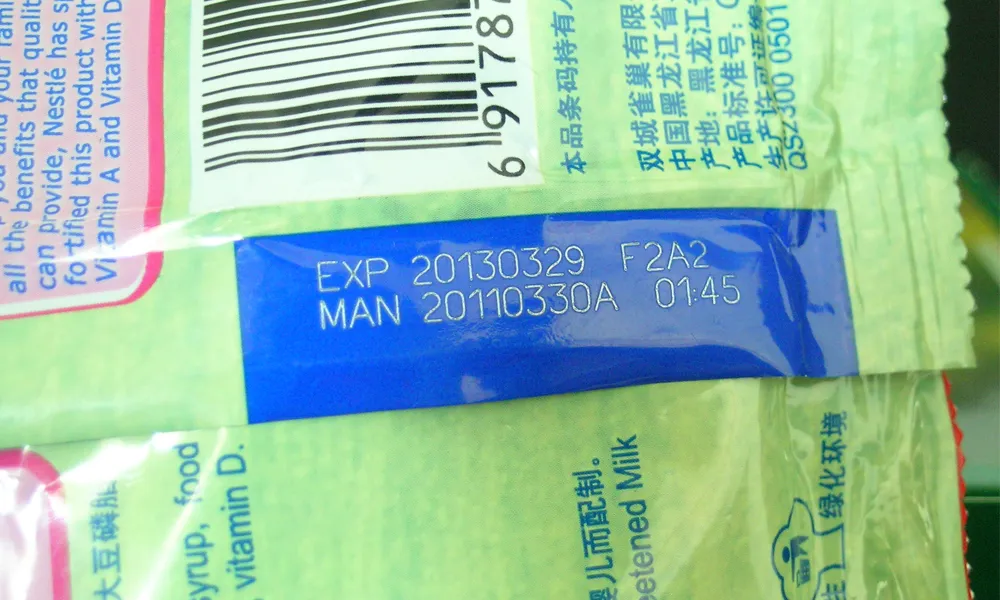

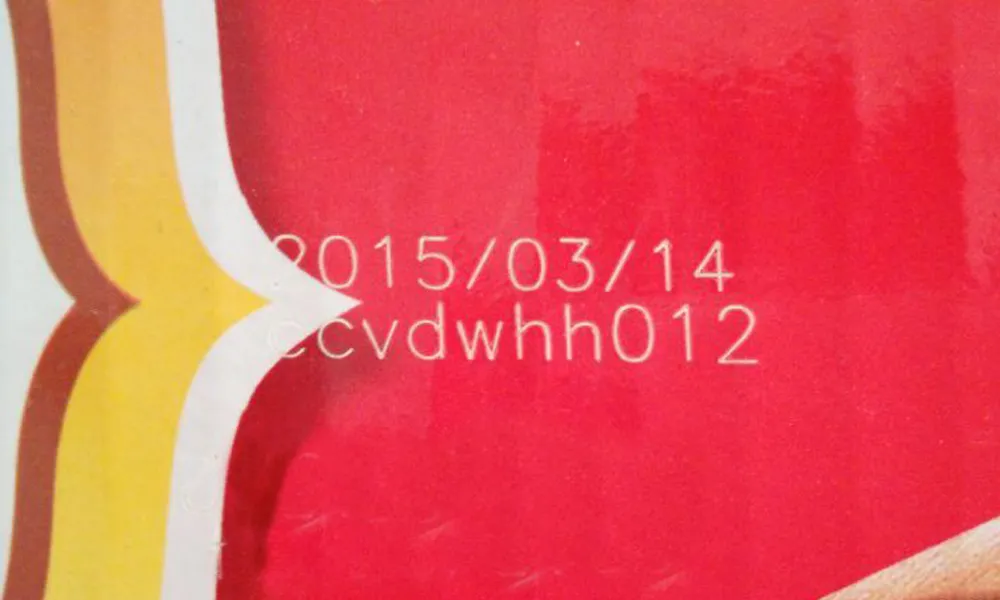

Diversified marking content (dates, batch codes, traceability codes, QR codes)

Automatic cleaning & easy operation

Perfectly matches high-speed production lines

It’s clear that laser marking machines will become the primary choice for the future of food packaging identification.

Before purchasing a laser marking machine, understanding the working principles and marking results on different packaging materials can help companies make smarter decisions.

Laser marking systems create permanent codes by interacting with the surface of packaging materials. Based on processing principles, laser marking can be divided into:

The laser beam heats the material, causing micro-melting or color contrast.

✔ Ideal for paper boxes, PET bottles, plastic film, aluminum foil, and coated packaging.

UV laser photons break chemical bonds with almost no heat effect.

✔ Perfect for thin films, laminated pouches, flexible food packaging, and heat-sensitive materials.

Laser type selection affects marking clarity, line speed, and durability—making correct model selection essential for food manufacturers.

Laser marking machines can deliver high-contrast, permanent codes across diverse materials:

Codes remain readable after freezing, heating, or high-pressure sterilization.

Widely used for snacks, sauces, frozen food, and ready-to-eat meals.

Resistant to abrasion, condensation, and corrosion.

Suitable for water, juice, edible oil, dairy drinks, etc.

No ink smearing or fading—even in high-speed bottling lines.

With the right laser system, manufacturers can achieve higher efficiency and more reliable traceability.

DAT Laser is widely recognized for its high performance, durability, and engineering expertise. Our solutions are specifically optimized for food packaging production lines.

✔ Extensive Industry Experience

Years of R&D and production experience; products used widely across global food factories.

✔ Optimized for Food Packaging Materials

Supports PET, vacuum bags, aluminum foil, plastic film, and metal packaging.

✔ Zero Consumables = Long-Term Cost Savings

No ink or solvent purchases, lower maintenance, lower operating cost.

✔ High-Speed, High-Definition Coding

Perfect for modern automated lines, ensuring permanent and scannable QR codes and date codes.

✔ Customizable Solutions

We provide tailored laser marking systems for:

Beverage production lines

Snack packaging

Frozen food packaging

Canned food and metal lids

Fresh food and agricultural products

✔ Full Technical Support

Installation guidance, operator training, and fast after-sales service.

✔ Free Sample Marking Test

Customers can submit packaging materials for free marking evaluation.

DAT Laser is committed to helping food manufacturers build smarter, more efficient, and more competitive production lines.

If your factory needs:

High-speed laser marking machines

Food packaging laser coding solutions

Permanent QR codes / variable data coding

Cost-efficient traceability systems

Free marking samples

DAT Laser is ready to support your production needs.

DAT Laser—Your reliable partner for professional, stable, and high-performance laser marking solutions.