DAT UV laser printer offer marking solution with seamless integration, superior code quality, and durable qulity for unmatched production reliability.

The seamless integration can greatly save space, are very friendly to manufacturers with small factories.

Permanent and high-contrast codes enabling product lifetime track and trace for pharmaceutical, medical device and cosmetic products.

The focusing spot is extremely small: the wavelength of the ultraviolet laser is 355nm, and the diameter of the focusing spot can be less than 3μm, which can achieve ultra-fine marking.

High contrast: good beam quality, clear and fine marking, meeting the precision processing needs of the high-end market.

Stable performance: Advanced optical system and control technology are adopted to ensure the consistency of the marking effect.

Low energy consumption: low power, low power consumption and low operating cost.

No thermal effect: Ultraviolet laser breaks the chemical bond of the material through photochemical reaction, and there is almost no heat-affected area in the processing process, avoiding material coking, deformation and other problems, and is especially suitable for heat-sensitive materials.

No mechanical stress: Non-contact machining reduces physical damage to the material and maintains the integrity of the workpiece.

No pollution: no ink or other chemicals required, the marking process is environmentally friendly and pollution-free.

Special material processing: suitable for the surface marking of cosmetics, drugs and food packaging bottles, the effect is fine and firm, which is better than ink printer.

Applicable to a variety of materials: markable metals, non-metallic and polymer materials, such as glass, ceramics, plastics, silicon wafers, flexible PCB boards, LCD LCD glass, etc.

High resolution: good beam quality, clear and fine marking to meet the precision processing needs of the high-end market.

Easy maintenance: the equipment has a compact structure and simple maintenance. Some models adopt a maintenance-free design, which reduces downtime.

Low energy consumption: low power, low power consumption and low operating cost.

Technical Specification | ||

Marking Parameters | Marking Range | 170mm × 170mm (Range optional: 200mm × 200mm, 300mm ×300mm etc.) |

Minimum Character | 0.2mm | |

Minimum Line Width | 0.05mm | |

Repetition Accuracy | ±0.003mm | |

Engraving Linear Speed | ≤7000mm/s | |

Laser Features | Type | UV Laser |

Output Power | 3W, 5W, 10W | |

Power Stability (8H) | <±5% | |

Beam Quality M2 | < 2 | |

Working Environment | Cooling | Air cooling |

Operating Temperature | 5℃ ~ 35℃ | |

Humidity Requirement | 40% ~ 80%, non-condensing | |

Power Requirement | 220V±10%/50HZ | |

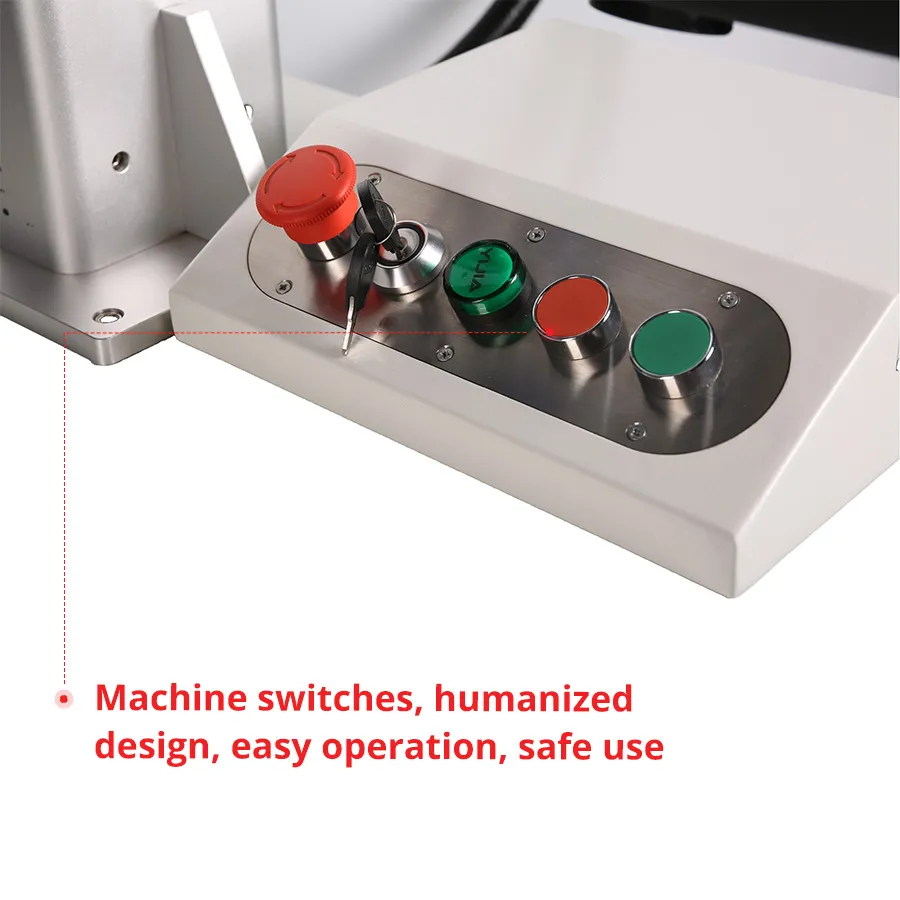

Excellent performance and simple operation.

High beam quality, small spot, accurate marking.

No thermal effect, the material does not deform and does not burn.

Fast marking speed and high efficiency.

Low cost and stable use.

QR code, bar codes, text and graphics can be well marked.

24-hour after-sales service.

Multi-material marking.

Mark faster and more accurate.

Contact With Us:

E-mail: doria@laserdat.com

Have a Questions? Call Us:

Whatsapp:

Add:

No. 181, ShiBai South Street, Luquan District, Shijiazhuang, Hebei